It is similar to filament yarn production. From the chips storage, the polymer is vacuum-fed to a dosing station on top of the extruder. Inside the extruder, it becomes melted and homogenized.

It is similar to filament yarn production. From the chips storage, the polymer is vacuum-fed to a dosing station on top of the extruder. Inside the extruder, it becomes melted and homogenized. Passing a filter system and a spin pump, the melt is fed into the spin beam or spinnerets, which form a curtain of filaments. The filaments are cooled by means of a stream of air in a blowing area, drawn by aerodynamic forces and then transported to the downstream discharge channel. For nonwovens, instead of a further stretching process for filament yarns, the filaments are swirled around and then deposited on the wire mesh belt as a random nonwoven. This web is transferred to a bonding calender that uses heat and pressure to set such physical properties as tensile strength and elongation of the final product. After cooling, the material can be wound.

Application:

1. Agriculture fields: UV treated products used in agriculture;

2. Household fields: tablecloth, furniture, disposable cloth;

3. Hygiene fields: surgical gowns, protective coverall, working garment, disposable hats, shoe cover etc.;

4. Sanitary fields: baby diaper, adult diaper, underpad etc.;

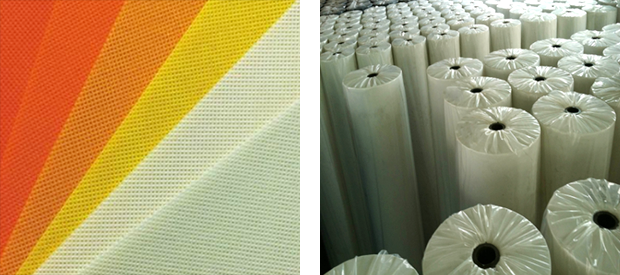

5. Shopping bags: many bright colors available.

Other Products: